Agentic P&ID Intelligence

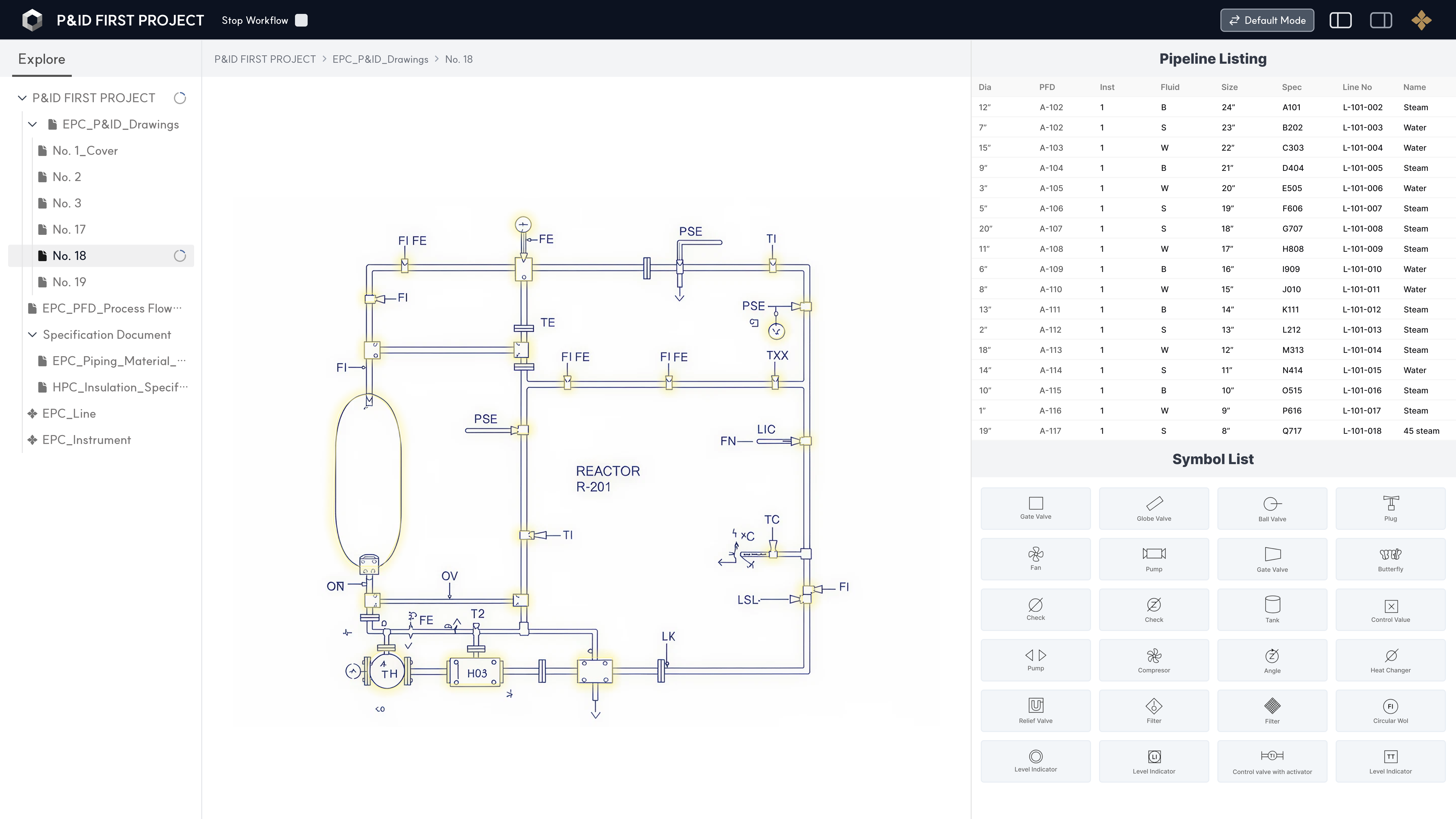

Automate P&ID drawing analysis and Material Take-Off extraction with multi-vision AI agents. What takes junior engineers weeks of manual tracing — our agents complete in hours with zero missed connections.

The Challenge in Construct

Industry-specific data silos and manual processes that slow down decision-making

2,000+ Pages of Dense P&ID Drawings

Every plant project involves thousands of P&ID pages with hundreds of piping symbols (ISA S5.1 standard) and 300+ sheets of technical specifications. Every connection matters — one miss means a construction error.

Weeks of Manual Work by Junior Engineers

Junior engineers read P&ID page by page, trace each pipe line, identify every valve and instrument, classify by company-specific rules, and enter data into Excel. Senior engineers then review and correct. This takes weeks — months for large plants.

General-Purpose Vision AI Fails Here

Standard AI vision models cannot handle P&ID drawings — they are too dense, symbols too specialized, and connections too critical. Tacit knowledge of experienced engineers is required to read them accurately. Junior engineers burn out from the tedium.

AI Capabilities for Construct

Purpose-built AI agents that understand your domain

Symbol Detection Agent

Identifies valves, instruments, equipment, and fittings — trained on ISA S5.1 symbology and project-specific legends.

Line Tracing Agent

Follows every pipe connection end-to-end. Captures line numbers, sizes, and specs. Never loses a branch.

Visual RAG Agent

References engineering standards, past project data, and company-specific classification rules to resolve ambiguities.

Code Generation Agent

Writes extraction scripts, applies company-specific MTO rules, and auto-generates structured output.

How It Works

From raw data to intelligent insights — powered by AI agents

DeepAuto Multi-Vision Agent System

No single AI model can do this. Multiple specialized models, coordinated by an agentic orchestrator.

Plant EPC — P&ID drawing analysis and Material Take-Off automation

The Challenge

Every plant project generates 2,000+ pages of dense P&ID drawings with hundreds of specialized piping symbols. Junior engineers had to read each page manually, trace every pipe connection end-to-end, identify every valve and instrument, classify materials by company-specific rules, and enter it all into Excel — for senior engineers to then review and correct. This took weeks per project, months for large plants. Junior engineers burned out from the tedium, turnover was high, and one missed connection could mean a costly construction error. General-purpose vision AI couldn't handle it — the drawings are too dense and the symbols too specialized.

Weeks of manual work → hours

What took junior engineers weeks of page-by-page tracing now completes in hours. The entire 460-sheet P&ID package for a plant project is processed automatically — no manual reading, no spreadsheet entry.

Human error → zero missed connections

Every pipe connection is traced end-to-end across all sheets. Cross-sheet references, branches, and junctions are all captured. The verification layer catches duplicates and conflicts that human reviewers would miss.

Junior engineer burnout → higher-value work

Junior engineers no longer spend months on repetitive P&ID tracing. They now focus on reviewing AI-generated output and handling edge cases — work that actually builds their engineering expertise.

One-off extraction → reusable knowledge

Company-specific classification rules, custom legends, and MTO formats are learned once and applied consistently across every project. Each new project benefits from everything learned before.

The Results

Explore Other Solutions

Ready to become

AI-first?

Schedule a 30-minute demo and see how DeepAuto can transform your enterprise data and workflows in weeks — not months.